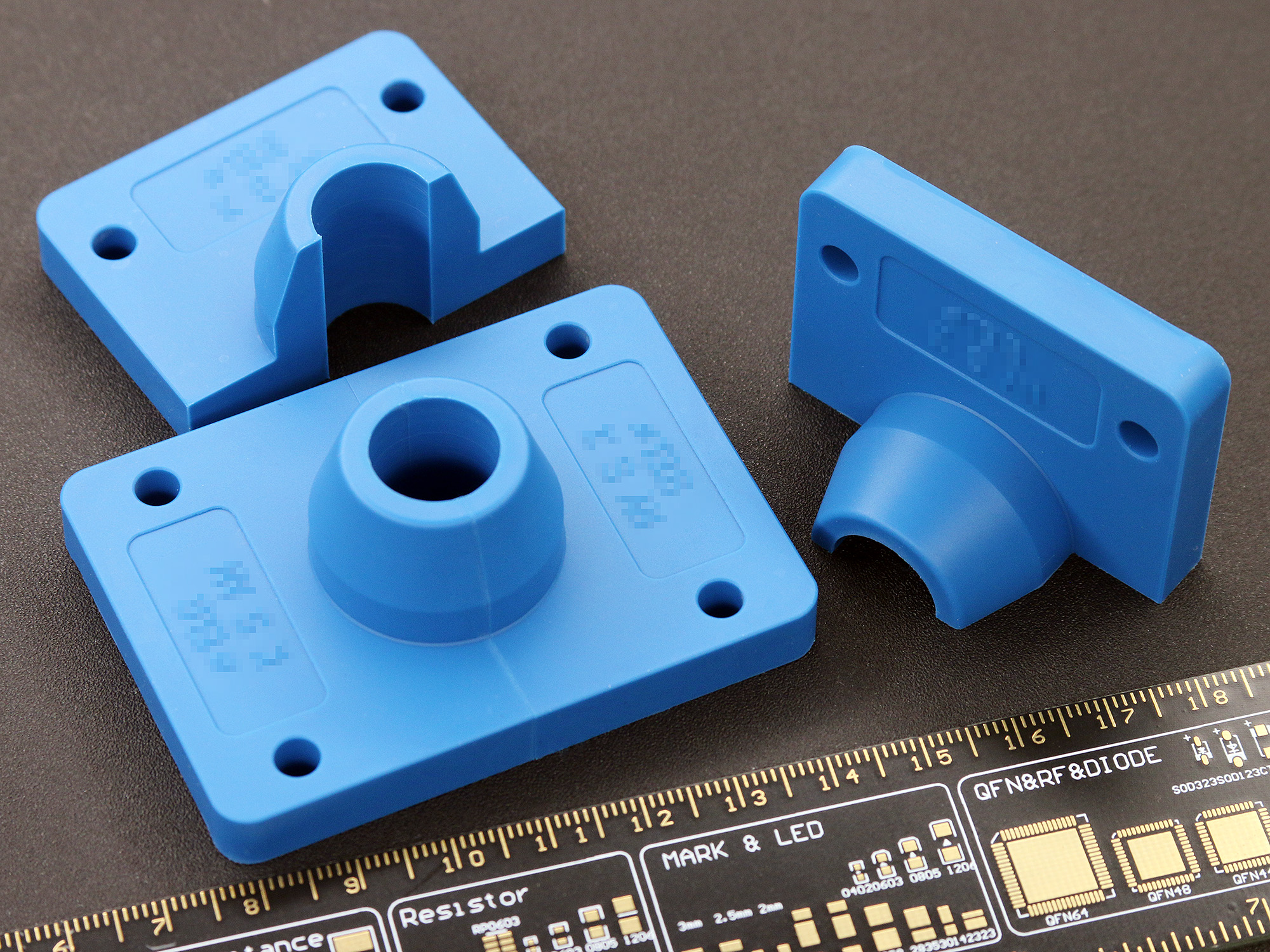

Silicone rubber products

We manufacture complex geometry parts from the highest quality addition-type silicone rubbers in following hardness options: Shore A 0 (basically gelly-like) to Shore A 50 (like pencil eraser).

These silicon grades have higher durability, better chemical and heat resistance than generic condensation-type silicones.

Our vacuum-assisted mixing and molding process and pressure/temperature controlled curing ensures void-free and bubble-free products.

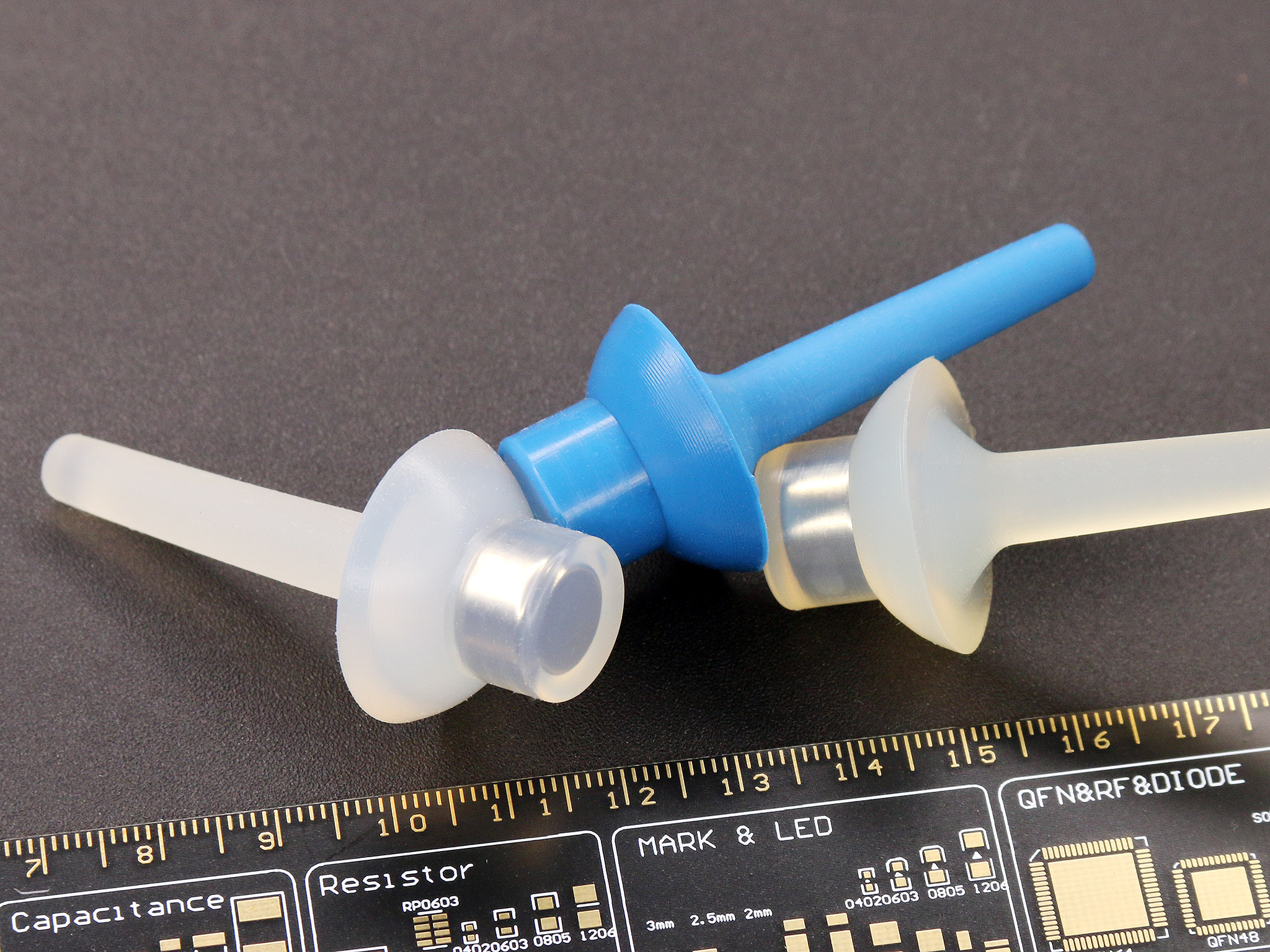

Some of these material grades can even be combined within a single product, eg. to have a tougher base to endure high service loads, while having softer parts for better fitting sealing.

Embedding metal or plastic components into the casting is also possible - like in this case, neodymium magnets are positioned precisely inside the silicone plugs.