Micro injection molding

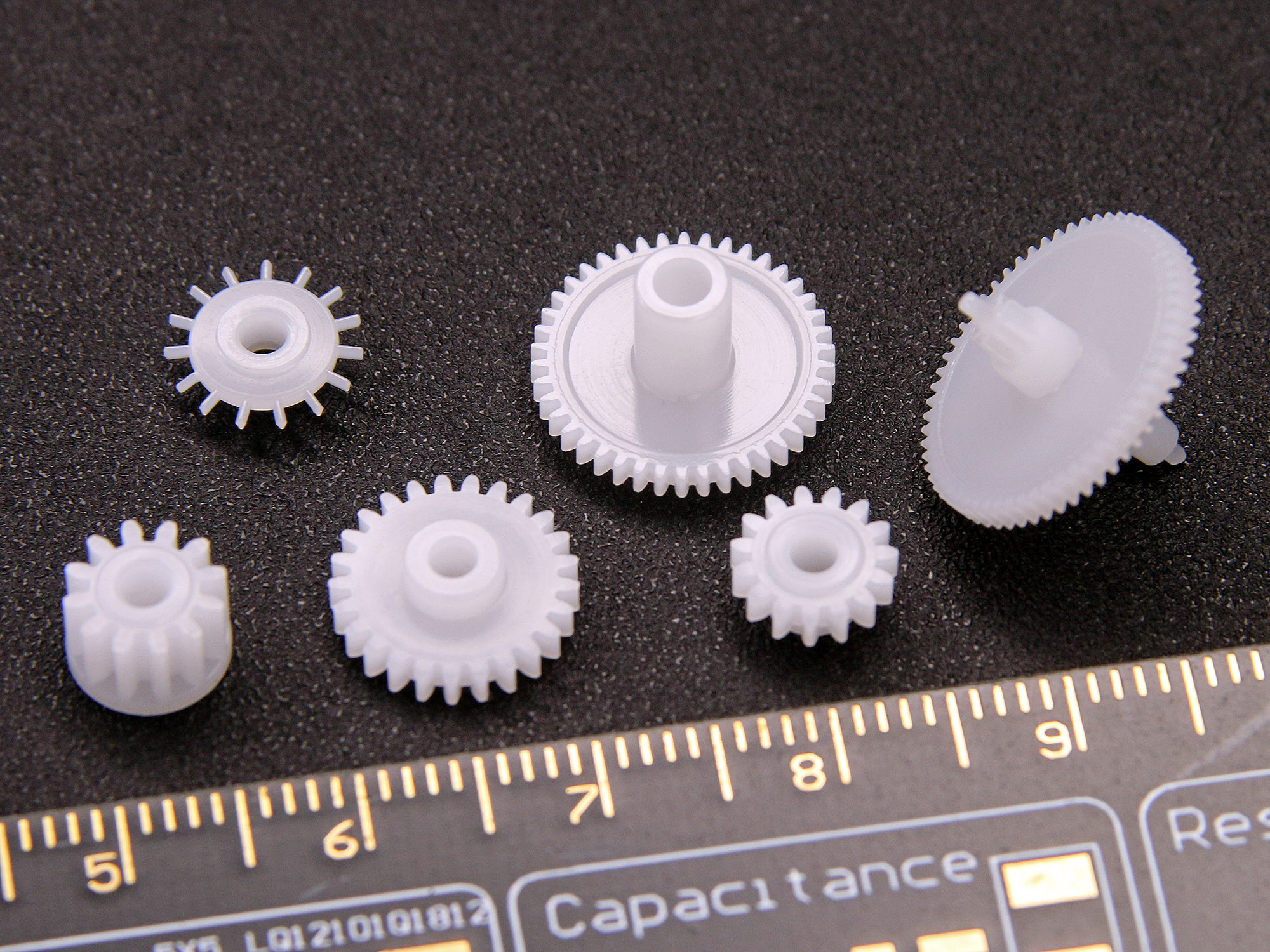

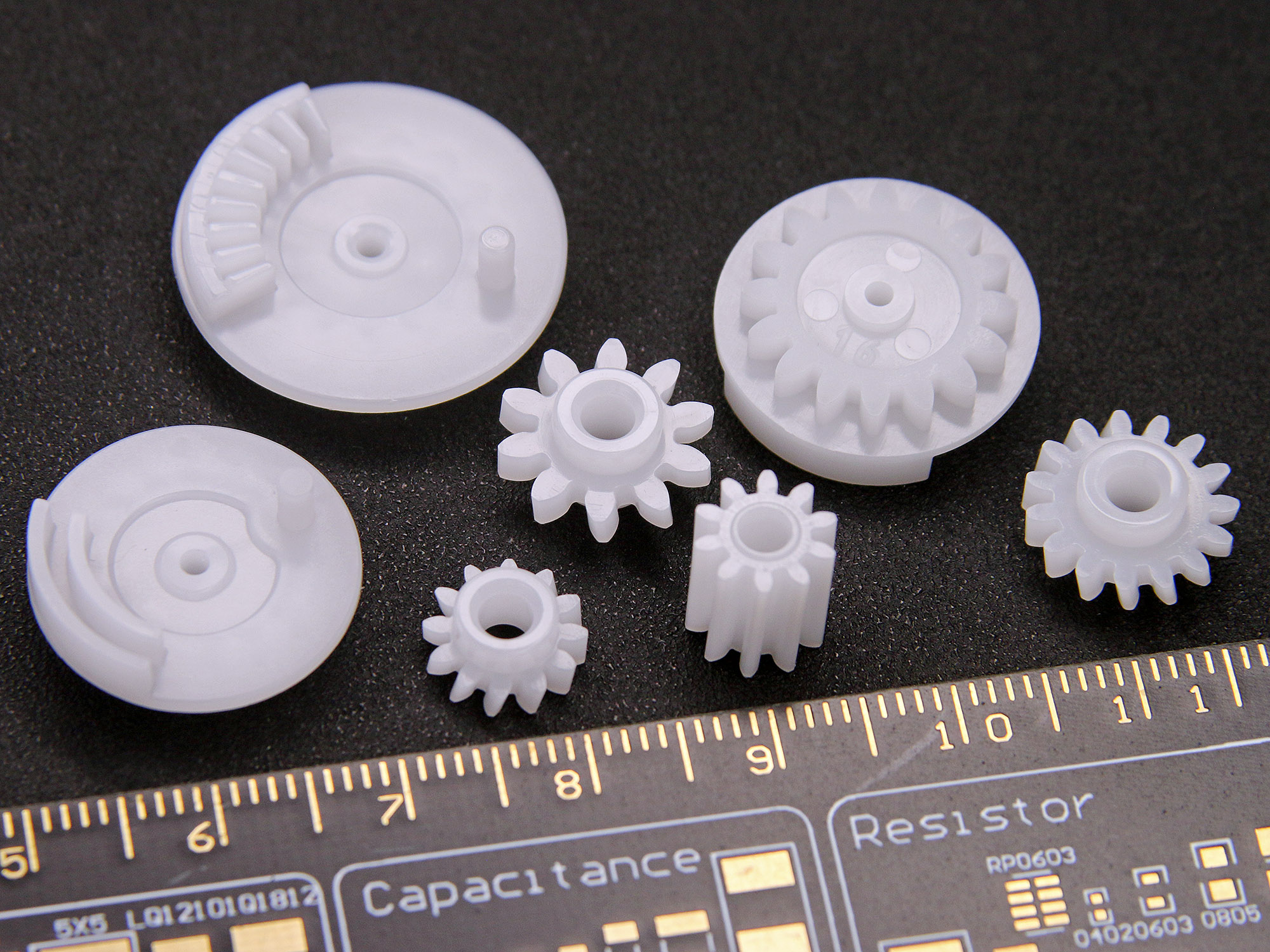

We can manufacture precision components in the range of 0.05 - 10 grams (basically from the size of a grain of rice to the size of a matchbox).

The scale on these images are in mm-s.

We can process a wide range of engineering and commodity plastics, mostly (but not limited to):

- POM (polyoxymethylene, e.g. Delrin)

- ABS (acrylonitrile butadiene styrene)

- PMMA (polymethyl methacrylate, e.g. Plexiglas)

- PC (polycarbonate, e.g. Lexan)

- LDPE/HDPE/PP (polyethylene, polyprolylene)

- TPE/TPU (thermoplastic elastomers, urethanes: flexible rubbery plastics)

Why us?

Injection molding is usually an expensive manufacturing method, suited for mass production due to the high initial costs.

But with us, even a few dozen pieces might be feasible and affordable, thanks to our streamlined processes and specialised equipment.

However we can also fulfil orders in the hundreds or weekly several thousands magnitude.